NEWS

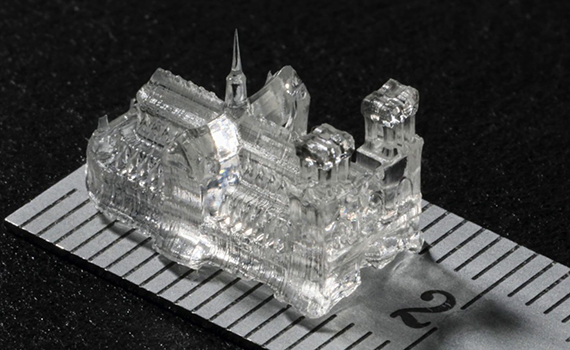

New technology prints tiny objects in seconds

Swiss researchers have developed a new high-precision 3D method for printing small soft objects.

According to specialists from the Lausanne Federal Polytechnic School, the innovative 3D printing method can be used to create detailed objects in record time. The ability to print hard parts of various textures (tissues, organs, hearing aids and mouthguards) makes the technology ideal for medicine and biology.

According to naukatv.ru, traditional 3D printing technologies create details layer by layer. The new technique is based on the principles of tomography. The printer works by sending a laser through a translucent gel (biological gel or liquid plastic). The laser causes the liquid to solidify during the polymerization process. Depending on the shape of the printed object, the algorithm accurately calculates where the rays should be directed, at what angle and in what quantity. Currently, the system is capable of producing two-centimeter structures with an accuracy of 80 micrometers. Now a team of engineers is working on new devices that will print larger objects (up to 15 centimeters).