NEWS

Using 3D Printing e to Repair Tracheal Damage

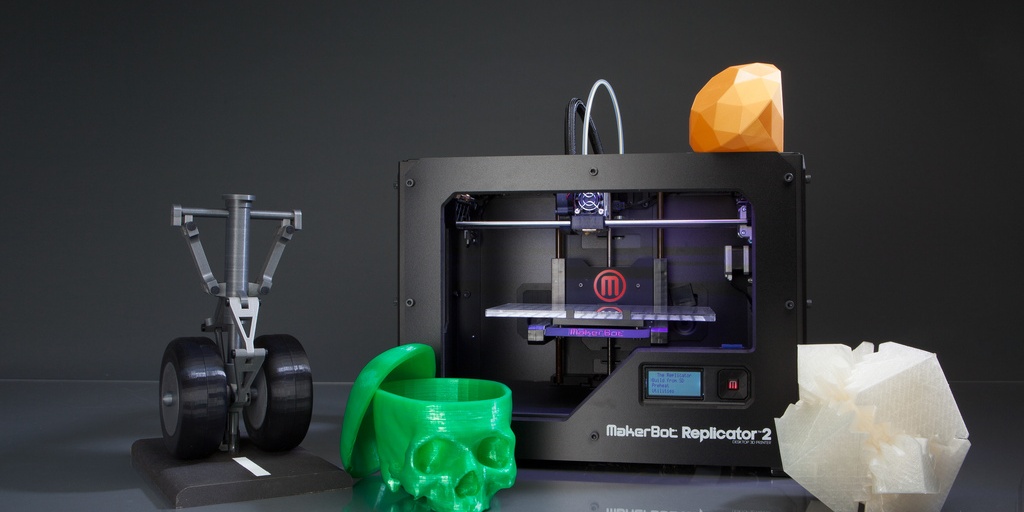

Investigators at The Feinstein Institute for Medical Research have made a medical breakthrough using 3D printing on a MakerBot Replicator 2X Experimental 3D Printer to create cartilage designed for tracheal repair or replacement. This is a first for medical research where regular MakerBot PLA Filament was used to 3D print a custom tracheal scaffolding, which was combined with living cells to create a tracheal segment.

The Feinstein Institute’s research combined two emerging fields: 3D printing and tissue engineering. Tissue engineering is like other kinds of engineering, except instead of using steel or computer code to make things, living cells from skin, muscle or cartilage are the raw material. Researchers at the Feinstein Institute know how to make cartilage from a mixture of cells called chondrocytes, nutrients to feed them, and collagen, which holds it all together. Shaping that cartilage into a nose or a windpipe is another matter. That’s where 3D printing comes in. A 3D printer can construct scaffolding, which can be covered in a mixture of chondrocytes and collagen, which then grows into cartilage.