NEWS

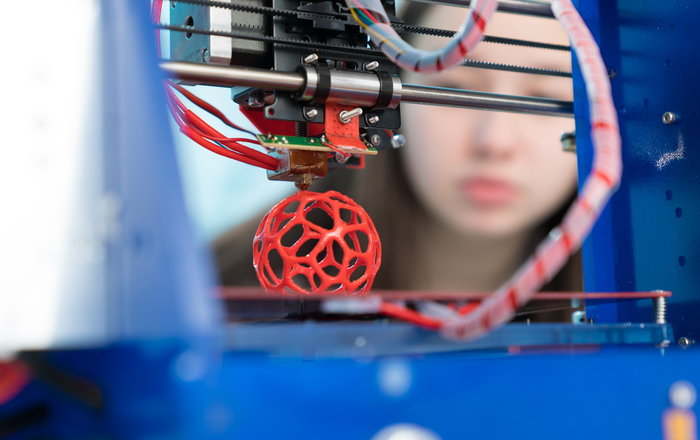

New technology of 3D-printing will create products from water and air

Three-dimensional (3D) printing allows for a short time to create finished products of any complexity from computer digital models. Researchers from the Institute of Organic Chemistry named after N.D. Zelinsky Academy of Sciences synthesized a unique material PEF, which allows to conduct three-dimensional printing cheaply and environmentally. Its full name is poly (ethylene-2,5-furandicarboxylate). The peculiarity of this material is that it is obtained from a natural substance - cellulose, which belongs to the category of the most promising renewable resources. In nature, cellulose is synthesized from carbon dioxide and water, available in the atmosphere in almost unlimited quantities. The source of energy for this reaction is sunlight.

The "recipe" for the new substance is simple: in the first stage, plant biomass (cellulose or fructose) is transformed into 5- (hydroxymethyl) furfural (5-HMF). Chemists know many techniques for this transformation. Further, 5-HMF is oxidized to 2,5-furandicarboxylic acid, which, after reaction with methanol, is converted to the corresponding ester. All three stages of this reaction from a practical point of view do not represent any complexity and are already scaled to industrial production. Despite its simplicity, 3D printing by PEF material was performed for the first time.

The resulting polymer showed high chemical stability, it is not oxidized, is resistant to the action of chemical solvents and does not decompose, being in the natural environment. Moreover, it can be used many times. Products made from such a polymer will be quite durable, and additive technologies, such as 3D printing, allow you to create an object of almost any complexity.

© All rights reserved. Citing to www.ict.az is necessary upon using news