NEWS

Light rays helped speed up the 3D printing process 100 times

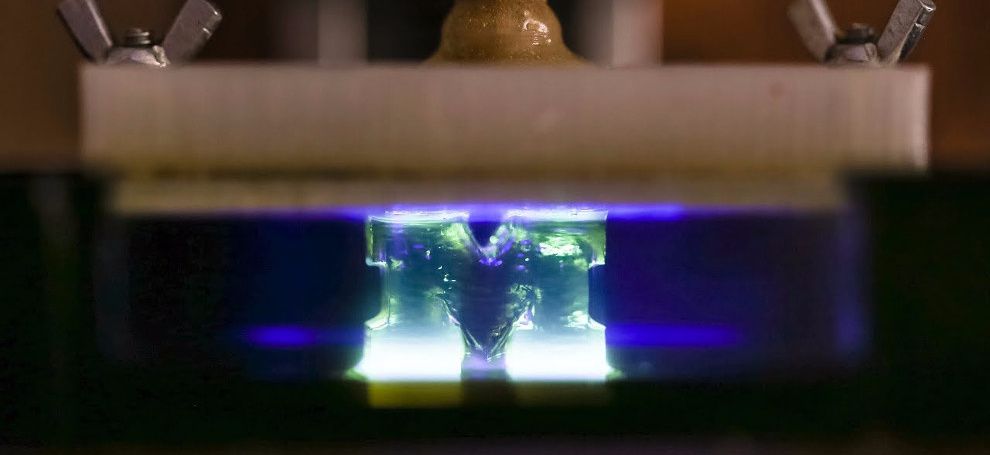

The University of Michigan (USA) has developed a new method of 3D printing. It allows you to create various three-dimensional objects, not layer by layer, as they are doing now, but entirely.

The researchers suggested using a special liquid resin and two light sources with different wavelengths. Rays help control the solidification of the material. The peculiarity of the new method is that one light source helps the resin to harden, and the second is designed to stop this process. Through this approach, researchers can control which part of the object has become solid and which area still remains in a liquid state.

Externally, the printing process is similar to casting. The object is “pushed” out of the resin tank. Rays gradually form the necessary solid object from this liquid material. Using the new method created a three-dimensional letter "M" and a miniature ship.

Engineers claim that products created using the new method are more durable. This is due to the fact that for objects printed in several layers, structurally weakened areas appear between the layers. Therefore, they are less durable.

According to scientists, if, when using a new printing method, special powders are added to the resin, the objects made from it may become more wear-resistant. The researchers also claim that the light printer does its job up to 100 times faster than traditional 3D-devices.